Agricultural Products

Prolube Lubricants: Elevate Your Farm Machinery Performance in Townsville, Queensland

Welcome to FCP Solutions, your premier destination in Townsville, Queensland, Australia, for top-quality agricultural lubricants. Our wide selection features Prolube Lubricants, a brand known for its exceptional performance in enhancing the lifespan and efficiency of farm machinery. Explore our range of Prolube agricultural products, including specialised tractor oils and harvester lubricants, all designed to meet the unique demands of your farming equipment operating in the harsh Australian environment...

FCP Solutions stock a range of products for all types of agricultural machinery that include:

- Engine Oils, tansmission oils, gear oils and greases for all agriculutral equipment and off road vehicles or engines.

- Cattle Rub for resistance to buffalo flies

- Cotton picker spindle wash for cotton picker machinery

- White oil for food, pharmaceutical and agricultural industries

All Prolube agricultural products from FCP Solutions are designed to provide numerous advantages that can greatly enhance the efficiency, performance, and longevity of agricultural machinery and equipment, these include:

-

Superior Lubrication Properties: Prolube oils are formulated with advanced additives and base oils that offer exceptional lubrication properties. This ensures that all moving parts within the agricultural equipment, including engines, transmissions, and hydraulic systems, are adequately lubricated. Proper lubrication reduces friction and heat, minimizing wear and tear on critical components.

-

Enhanced Engine Protection: All Prolube oils provide a robust protective barrier to engine components, even under extreme operating conditions. They resist thermal breakdown and maintain their viscosity, which is crucial for safeguarding engine parts from premature wear. This enhanced engine protection translates to longer engine life and reduced maintenance costs.

-

Improved Fuel Efficiency: Agricultural equipment often operates in demanding conditions, and fuel efficiency is a critical concern for operators. Designed to reduce internal engine friction, resulting in improved fuel efficiency, Prolube oils result in an engine running more efficiently, they generate less heat, consume less fuel, and experience fewer issues that can lead to engine failure.

-

Exceptional High-Temperature Stability: Agricultural equipment is frequently subjected to high-temperature environments, especially during prolonged operation. Our oils are engineered to maintain their stability even under extreme heat. This stability prevents the formation of harmful deposits and sludge within the engine, which can impede performance and ultimately lead to engine failure.

-

Minimized Downtime and Maintenance Costs: By using Prolube oils, agricultural equipment operators can minimize downtime and reduce maintenance costs. These oils help prevent early wear and damage, ensuring that equipment operates at peak performance for longer periods between service intervals. This not only enhances productivity but also saves on repair and replacement expenses.

When to change agricultural machinery oil?

Changing oil in agricultural equipment is crucial for maintaining the proper functioning of the machinery and extending its lifespan. The frequency of oil changes depends on several factors, including the type of equipment, the manufacturer's recommendations, and the operating conditions. Here are some general guidelines and early signs of wear to look out for:

1. Manufacturer's Recommendations: Always start by consulting the equipment's owner's manual or contacting the manufacturer for specific oil change intervals. They will provide the most accurate information tailored to your equipment's make and model.

2. Hours of Operation: Many agricultural equipment manufacturers recommend changing oil after a certain number of hours of operation. This could range from 100 to 500 hours for engine oil and anywhere from 500 to 2000 hours for hydraulic oil applications. Ina ll cases it is vital to keep a log of your equipment's operating hours to schedule oil changes accordingly to ensure longevity and efficient operation of agricultural equipment.

3. Seasonal Changes: Agricultural equipment often experiences increased usage during planting and harvest seasons. Consider changing the oil before or after these peak periods to ensure the equipment is in top condition when needed the most.

4. Oil Analysis: Some farms and agricultural operations use oil analysis services to assess the condition of the oil and detect early signs of wear. This involves taking oil samples and sending them to a lab for testing. The lab can provide information on the oil's condition and the presence of contaminants or excessive wear particles.

Early Signs of Wear to Look Out For:

- Oil Discoloration: Fresh engine oil is typically translucent and amber in color. As it becomes contaminated with dirt and engine byproducts, it may darken or become cloudy. If you notice a significant change in oil color, it's a sign that the oil may need changing.

- Increased Oil Consumption: If your equipment starts consuming more oil than usual, it could indicate internal wear or oil leakage. Monitor the oil level regularly, and if you notice a sudden drop, investigate the cause.

- Knocking or Unusual Noises: Unusual engine noises, such as knocking or tapping, can be indicative of internal engine wear. These noises may become more pronounced as wear progresses.

- Reduced Performance: If your equipment experiences a decrease in power, efficiency, or overall performance, it could be a result of engine wear. This may be accompanied by increased fuel consumption.

- Smoke Emissions: Excessive smoke from the exhaust, especially if it's black or blue, can be a sign of oil burning in the engine, which can be caused by worn piston rings or valve seals.

- Oil Pressure Warning: Modern equipment often has oil pressure warning lights or gauges. If you see a sudden drop in oil pressure or receive a warning, it's crucial to address it promptly to prevent engine damage.

The frequency of oil changes for agricultural equipment should be based on manufacturer recommendations, operating hours, and seasonal usage patterns. Regularly inspecting the oil for signs of wear and monitoring equipment performance can help catch issues early and ensure the equipment operates efficiently and reliably. Preventive maintenance is key to minimizing downtime and costly repairs in the long run.

By choosing Prolube agricultural oil and lubricant products from FCP Solutions when it is time to conduct your oil changes, farmers can expect improved equipment performance, extended equipment lifespan, reduced operating costs, and enhanced sustainability—all essential factors for a successful and thriving agricultural enterprise. Contact us today in Townsville and take the first step toward improving your agricultural equipment's performance and longevity

If your unsure on what you require or want to make certain of a selection please call (07) 4725 2166 or click the button below to email us.

Prolube Aglube MF STOU Super Tractor Oil Universal SAE: 20W40

AU From $45.50

or 4 payments of $11.38 with

Learn more

Learn more

Prolube Agtrans 410 SAE 10 Allison C4, CAT TO-4 Transmission / Hydraulic Fluid

AU From $165.00

or 4 payments of $41.25 with

Learn more

Learn more

Prolube Agtrans 430 SAE 30 Allison C4, CAT TO-4 Transmission / Hydraulic Fluid

AU From $41.30

or 4 payments of $10.32 with

Learn more

Learn more

Prolube Agtrans 450 SAE 50 Allison C4, CAT TO-4 Transmission / Hydraulic Fluid

AU From $169.00

or 4 payments of $42.25 with

Learn more

Learn more

Prolube Agtrans TTF GL4 80W Universal Tractor Transmission Fluid (UTTO)

AU From $45.00

or 4 payments of $11.25 with

Learn more

Learn more

Prolube HVX Turbo 15W50 CI-4 SL High Performance Diesel Engine Oil

AU From $45.50

or 4 payments of $11.38 with

Learn more

Learn more

Prolube Hyplex S Series ISO 68 Antiwear Hydraulic Oils

AU From $35.40

or 4 payments of $8.85 with

Learn more

Learn more

Prolube Ultrafleet 15W40 CI-4 SL High Performance Diesel Engine Oil

AU From $12.95

or 4 payments of $3.24 with

Learn more

Learn more

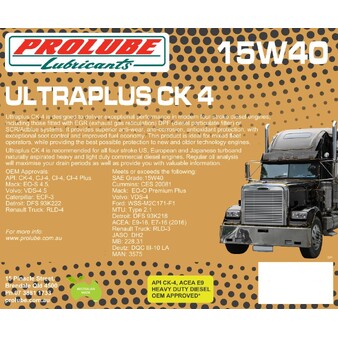

Prolube Ultraplus 15W40 CK-4 High Performance Heavy Duty Diesel Engine Oil

AU From $46.50

or 4 payments of $11.62 with

Learn more

Learn more