Hydraulic Oil Products

Hydraulic Oil Solutions from Prolube Lubricants

Prolube Lubricants hydraulic oil products from FCP Solutions are engineered to deliver unmatched performance and reliability in the most demanding applications across Australia. Formulated with cutting-edge technology to ensure superior lubrication, reduced wear and tear, and enhanced equipment longevity. When it's time to change your old hydraulic fluid FCP Solutions can provide the full range of hydraulic oilproducts to suit any application. Our collection features industry-leading formulations, including ISO hydraulic oils, anti-wear hydraulic oils (AW), and high viscosity index (HVI) hydraulic oils, ensuring optimal lubrication for a wide array of hydraulic systems...

At FCP Solutions, we take pride in being your go-to supplier for Prolube lubricants, delivering excellence to customers throughout Australia. Whether you're in Rockhampton, Mackay, Cairns, or the Atherton Tablelands, we've got you covered. Our dedicated team is committed to providing swift and reliable nationwide shipping, ensuring that businesses and enthusiasts alike can access Prolube's premium hydraulic oils with ease. Experience the power of seamless machinery operation with our carefully selected range, tailored to exceed the expectations of North Queensland's demanding industrial landscapes.You can expect reduced downtime, increased productivity, and significant cost savings through improved efficiency and equipment protection. Trust in Prolube Lubricants premium hydraulic oils from FCP Solutions to keep your machinery operating at its peak, ensuring a seamless and profitable operation for your business.

When to Change Hydraulic Oil?

The frequency of hydraulic oil changes in hydraulic systems can vary depending on several factors, including the type of hydraulic system, the operating conditions, and the quality of the oil used. However, as a general guideline, hydraulic oil should typically be changed every 1,000 to 2,000 hours of operation or at least once a year, whichever comes first. It's essential to consult the manufacturer's recommendations and perform regular oil analysis to determine the optimal change interval for your specific hydraulic system.

Here are some early signs of wear and issues to look out for when monitoring your hydraulic system:

-

Decreased Performance:

- Slower or less responsive hydraulic actuator movement.

- Reduced lifting or pushing capacity.

- Inconsistent or jerky movements.

-

Increased Noise:

- Unusual or louder-than-normal hydraulic pump or motor noises.

- Hissing, whining, or grinding sounds from the hydraulic system.

-

Elevated Operating Temperatures:

- Higher-than-usual operating temperatures, which can indicate increased friction and inefficiencies.

-

Leaks:

- Visible hydraulic fluid leaks or puddles around hoses, fittings, or components.

- Sudden drops in hydraulic fluid levels in the reservoir.

-

Contaminated Oil:

- Discoloration of the hydraulic oil (e.g., darkening or cloudiness).

- Presence of foreign particles or debris in the oil.

- Foaming of the oil, which can reduce lubrication effectiveness.

-

Increased Vibration:

- Excessive vibration in the hydraulic system, which can be felt or observed.

-

Reduced Filter Life:

- Frequent clogging of hydraulic filters or a shortened filter lifespan.

-

Unusual Odors:

- Strange or burnt smells from the hydraulic system, which can indicate overheating or oil degradation.

-

Loss of System Control:

- Inability to maintain precise control over hydraulic movements or functions.

-

Changes in Fluid Properties:

- Changes in the viscosity or density of the hydraulic oil, affecting its ability to transmit pressure effectively.

Regularly monitoring these signs of wear and conducting routine maintenance and oil analysis can help identify problems early, prevent major breakdowns, and extend the life of your hydraulic system. Additionally, following proper maintenance practices, such as keeping the system clean, tightening fittings, and ensuring proper filtration, can contribute to the longevity of hydraulic components and reduce the frequency of oil changes. Always refer to the manufacturer's guidelines and recommendations for your specific hydraulic system to ensure optimal performance and reliability.

If your unsure on what you require or want to make certain of a selection please call (07) 4725 2166 or click the button below to email us.

Prolube Agtrans 410 SAE 10 Allison C4, CAT TO-4 Transmission / Hydraulic Fluid

AU From $165.00

or 4 payments of $41.25 with

Learn more

Learn more

Prolube Agtrans 430 SAE 30 Allison C4, CAT TO-4 Transmission / Hydraulic Fluid

AU From $41.30

or 4 payments of $10.32 with

Learn more

Learn more

Prolube Agtrans 450 SAE 50 Allison C4, CAT TO-4 Transmission / Hydraulic Fluid

AU From $169.00

or 4 payments of $42.25 with

Learn more

Learn more

Prolube Agtrans TTF GL4 80W Universal Tractor Transmission Fluid (UTTO)

AU From $45.00

or 4 payments of $11.25 with

Learn more

Learn more

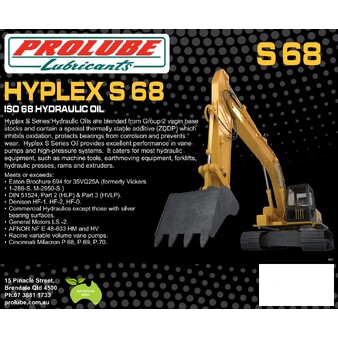

Prolube Hyplex S Series ISO 68 Antiwear Hydraulic Oils

AU From $35.40

or 4 payments of $8.85 with

Learn more

Learn more